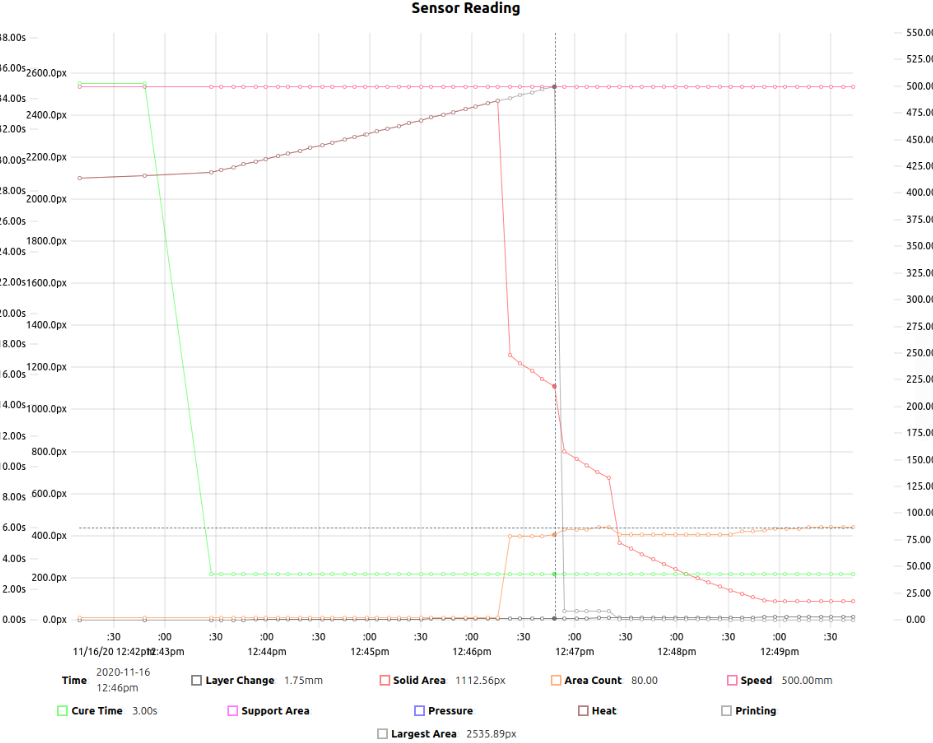

A major blind spot on resin 3D printing is lack of measurement tools for 3D manufacturers, resin producers and 3D printing enthusiasts. NanoDLP Analytic Dashboard is a new tool available to monitor both internal data and external sensors. It makes it easy to correlate data from multiple sources. It could be used together with flexible real-time code JS support to make NanoDLP decide many actions in during printing. For example pressure detection and many real-time decisions could be taken.

Internal Data Sources

Currently possible to see realtime flow of data from current sources:

- Slicer data – Solid Area, Area Count, Largest Area

- Current layer information: Cure time, Speed and etc

External Sources

It include many sensors that could be read such as:

- Moister

- Resin Level

- Driver Amper

- Light Intensity

- Pressure

- Temperature

Currently common sensors and platforms already tested

- HX711

- OpenScale

- Serial Device Reading (Comma Separated)

Features of NanoDLP Analytic Dashboard

Currently available NanoDLP features are:

- It read values both during idle and printing time. Many KPIs only available during printing.

- Both realtime monitoring and long term KPI visualization available

- Ability to reset collected data

- CSV export

How to Use NanoDLP Analytic Dashboard?

You can go to setup menu / tools page then click analytic dashboard button. Data collection will start only after visiting this page.

Latest Posts

NanoDLP Software for SLS 3D Printers

One of the less known aspect of the NanoDLP is the ability to control both SLS and Laser SLA 3d printers. SLS is type of 3D printers create shapes by using laser to heat powders. Compare to SLA (Resin) printers quality is lower but additional support structure is not needed and high-end SLS machines use […]

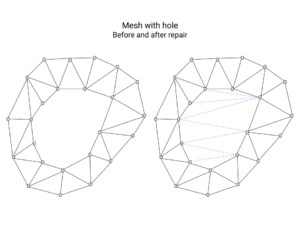

STL Mesh Repair

Technology Of Mesh Repair Tool NanoDLP Repair tool is developed using Golang language which makes it available on all platform including on your browser Simple interface Of Mesh Repair Tool We don’t ask you for any complex input. Just import your STL model and sit back until it’s repaired. Features Of Mesh Repair Tool Our […]

Web Browser-Based SLA 3D Printer Slicer

SLA 3D printer web browser based slicer rely on your browser resources to slice 3D files instead of Raspberry Pi (or other host SBCs)