3D Printer SLA slicer software for LCD / DLP 3D printers is one of the most important aspects of SLA 3D printing because it affects both quality and success of the prints.

What is the slicing process?

3D printer slicing is the process which converts 3D objects to specific data for printing slicing. 3D slicer operates this process. The data needed for each 3D printing technology is different. Here we will focus on slicer for LCD and DLP (SLA) type printers.

For so called resin SLA 3D printers, data needed for 3D printing process is a series of slices of an object (image frame) in different heights.

What is the slicing software?

Slicing usually is a multi stage process which could be carried out on CPU or GPU. Usually GPU slicers are much faster than CPU ones but also less flexible and could not run on many systems as CPU one.

Source data for slicing process is a 3D object in different formats, but right now most of the 3D printer users use STL and OBJ file formats. The STL file format contains the coordination of triangles tightly packed together. The slicing process could be done with different strategies and algorithms. Generally the below stages are carried out by 3D slicers:

- Read 3D objects into memory

- Cut / Slice 3D objects in different heights and generate polygon in a 2D surface

- Rasterize polygons

In stage 2, the object that is already sliced and some of the export formats such as SLC, could be exported.

Important aspects of a slicer software

Performance

Some of the source 3D files could be huge in size up to couple of gigabytes, specially the exports of cloud points from the 3D scanners (Dental market). Also the 3D editor that use nurbs instead of mesh (eg. Rhino) are used to have large export files.

Many slicers require more memory a few times more than actual STL file size to do processing. Also for CPU based slicers slicing process could even take up to hours to do.

There are many solutions such as meshlab to decrease size of STL by simplifying objects.

Features

Some slicers provide only basic functionalities but there are many features which are better to be handled on slicer level. Those features include:

- Surface improvements

- Polygon / Mesh correction and modifications

- Image processing

- Verification and overhang detection

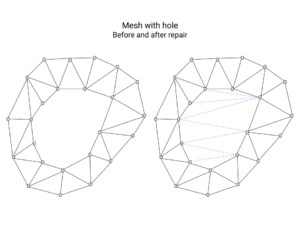

Faulty Triangle Handling

Many programs exporting malfunctioned triangles. How resilient the slicer is, is a very important aspect of the slicer as it could cause faulty prints.

Some of the common issues on mesh level are:

- Shells

- Gap between triangles

- Wrong Normals

- Flipped Triangles

- Duplicate Triangles

- Orphaned Triangles

NanoDLP slicer includes repair functionality which could fix majority of the issues.

How NanoDLP SLA slicer works

NanoDLP slicer which is integrated in both NanoDLP and NanoSupport, is a CPU based slicer. Considering that the NanoDLP primary platform is Raspberry Pi, many technical choices are considered as Pi’s limitations.

The main stages of NanoDLP slicer are mentioned below:

- Loading 3D object

- Optimize input including deduplication

- Generate 3D preview on CPU

- Check matching triangles on each level (height)

- Cut them, and produce polygon

- Correct triangle

- Apply vector processes

- Pre-rasterization processes

- Rasterize

- Post-rasterization processes

- Run multi layer algorithms

- Save layers

- Verify output and island detection

NanoDLP SLA slicer performance

NanoDLP slicer performs very well. It’s main target platform is Raspberry Pi with very limited resources.

SLA Slicer Memory Usage

The memory that is needed to slice an STL file is around the same as an STL file size. So on 2GB memory you can slice 2GB STL file. Also NanoDLP supports multipass slicing which could slice an STL with any size, but it is super slow and not advised. In case of a very large STL file, it is better to use NanoSupport or NanoDLP Remote Slicing feature.

SLA Slicer Speed

NanoDLP utilizes all cores on your system. It is highly optimized for the speed.

On Skylake i7, slicing a 250MB STL file to a ZIP file that contains 256 PNG layers and 3D preview, takes 8.3s to finish. It includes all verification and statistic generation.

User time (seconds): 18.66

System time (seconds): 0.42

Percent of CPU this job got: 230%

Elapsed (wall clock) time (h:mm:ss or m:ss): 0:08.29

Average shared text size (kbytes): 0

Average unshared data size (kbytes): 0

Average stack size (kbytes): 0

Average total size (kbytes): 0

Maximum resident set size (kbytes): 272900NanoDLP SLA slicer features

NanoDLP slicer supports many advanced slicing features and many of them are not available on the other slicers, such as:

- Anti-Aliasing

- 3D Anti-Aliasing

- Dimming

- Lens Distortion Correction

- Multi-cure

- Mask

- Island detection and layer verification

- Slicer level hollowing

Latest Posts

NanoDLP Software for SLS 3D Printers

One of the less known aspect of the NanoDLP is the ability to control both SLS and Laser SLA 3d printers. SLS is type of 3D printers create shapes by using laser to heat powders. Compare to SLA (Resin) printers quality is lower but additional support structure is not needed and high-end SLS machines use […]

STL Mesh Repair

Technology Of Mesh Repair Tool NanoDLP Repair tool is developed using Golang language which makes it available on all platform including on your browser Simple interface Of Mesh Repair Tool We don’t ask you for any complex input. Just import your STL model and sit back until it’s repaired. Features Of Mesh Repair Tool Our […]

Web Browser-Based SLA 3D Printer Slicer

SLA 3D printer web browser based slicer rely on your browser resources to slice 3D files instead of Raspberry Pi (or other host SBCs)