It is a masking screen (Monochrome) which nowadays has been widely used in the resin printing industry. But why?

Printer

Frankly, there are dozens of reasons which are appurtenant to the printer itself.

By using Monochrome LCD screens, a printer can use much less energy than the normal RGB ones although there is no need for regular maintenance as such.

One of the key benefits of them is about time. They are known for their faster printing process than the color screens. Maybe you say, “OK, there is no much difference between them”, But without a doubt, regarding extremely large files, the printing speed is of paramount importance. Once you know the fact that they are somehow about two times faster than the regular RGB ones, you may be evinced by a burning desire to take a look at them.

Process

By using Monochrome LCD screens, the process could be done with a remarkably swift cure time. Thus, the super speedy cure times induces faster print time.

Additionally, the exposure time could be significantly decreased. In other words, the process can achieve layer cure times of a very few seconds which allows for much faster exposure settings. As mentioned, these screens allow for very short layer exposure times. Hence this leads to a huge time reduction; roughly one quarter of the time which is needed for RGB screens.

Longevity

Monochrome LCD screens have much longer lifespan than the normal color ones. It is worth mentioning with proper use they can last several thousand hours. Because of that, they have stable performance during long term printing. It is said that they are four times longer in lifespan than the others.

NanoDLP

You need to select “Non-Standard Monochrome” on “Setup > Machine Settings > Display Controller > Non-Standard Monochrome” to use monochrome display on NanoDLP.

Cautious

– Keep in mind unnecessarily high exposure time settings can also shorten the life of a Monochrome LCD screen.

– Keep In mind these screens have a higher cost than the normal RGB ones due to their smaller inventory.

Conclusion (Monochrome vs RGB)

+ Printer uses less energy

+ Faster printing; double times

+ Reduce exposure time; one quarter

+ Longer life span; four times

+ Faster cure time

– Higher cost

As a matter of fact, Monochrome LCD screens could significantly enhance the printing efficiency which leads to more stable performance for the entire printing process.

Latest Posts

NanoDLP Software for SLS 3D Printers

One of the less known aspect of the NanoDLP is the ability to control both SLS and Laser SLA 3d printers. SLS is type of 3D printers create shapes by using laser to heat powders. Compare to SLA (Resin) printers quality is lower but additional support structure is not needed and high-end SLS machines use […]

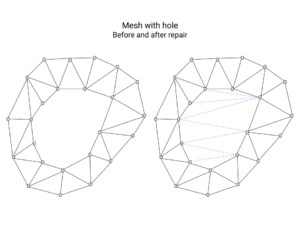

STL Mesh Repair

Technology Of Mesh Repair Tool NanoDLP Repair tool is developed using Golang language which makes it available on all platform including on your browser Simple interface Of Mesh Repair Tool We don’t ask you for any complex input. Just import your STL model and sit back until it’s repaired. Features Of Mesh Repair Tool Our […]

Web Browser-Based SLA 3D Printer Slicer

SLA 3D printer web browser based slicer rely on your browser resources to slice 3D files instead of Raspberry Pi (or other host SBCs)